That is the essence of why they are so massive, inconvenient, and destructive to your geometry.Īdditionally, STLs do not carry any machine information, settings for printing, or any other helpful information needed to recreate the file.

Therefore, only raw information can be carried over. Have you ever wondered why your STL can sometimes be as much as 10x the file size of your original file? Well, STLs are a mesh-based architecture, so they cannot store information as a mathematical representation.

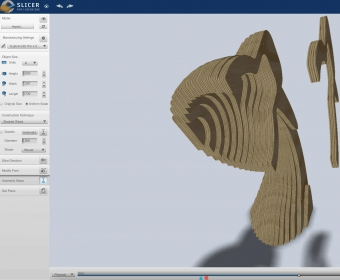

Some people still experience faceted prints of their parts because STLs interpret your data and essentially create a facsimile of your part, not an accurate representation. With that context in mind, it makes a lot of sense why STL format was created to begin with - translating curves and compound surfaces into machine data would be an astronomical amount of code to run. STL files were designed with additive manufacturing in mind, translating design data, typically NURBS or BREP based, into a mesh for 3D printers to interpret. It will be live and you can ask any questions to our CTO, Miguel Calvo.STL format is ancient in computer terms, as it was first released in 1987 by 3D systems. We’re hosting a free tech demo on February 7. Reliable bed tilt compensation (no more thumbscrews) 2.4 and 5 GHz Wi-Fi A 1080p camera (mounted higher for a better view) Compatibility with 280+ Marketplace materials Compatibility with S5 project files (no reslicing needed) And a whole lot more The UltiMaker S7 also includes quality of life improvements: We also reversed the front fan direction (fewer plastic hairs, less maintenance), made the print core door magnets stronger, and add a sensor that helps avoid flooding. This effectively makes it much harder to not achieve a perfect first layer, improving overall print success. The re-engineered print head has an inductive sensor which reduces noise when probing the build plate. Along with that, 4 pins and 25 magnets make it easy to replace the flex plate perfectly – even with one hand. But we also don’t recommend using or adhesion structures for UltiMaker materials (except PC, ’s PC). Not only do you not need tools to pop a printed part off.

A PEI-coated flexible steel build plate makes a big difference to productivity. The build stack has also been completely redesigned. To further enclose the build chamber the S7 only has one magnetically latched door. This filters the exhaust air of every print and also improves build temperature stability. It now includes an integrated Air Manager. The UltiMaker S7 is built on the success of the UltiMaker S5 and its design decisions were heavily based on feedback from customers.

0 kommentar(er)

0 kommentar(er)